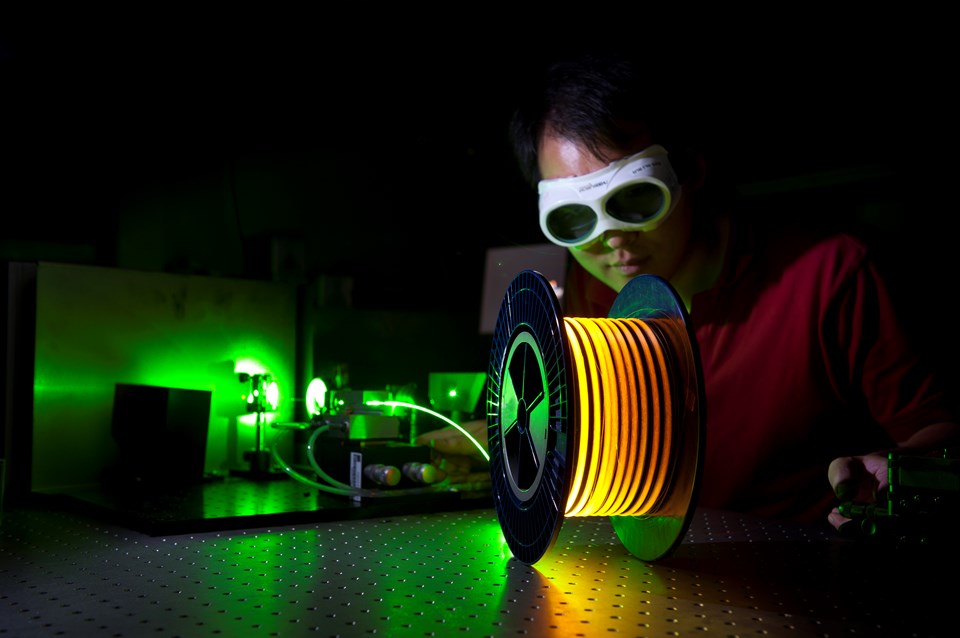

Revolutionising industrial material processing

The integration of lasers into optical fibres by pioneering research at the University of Southampton has led to the creation of a new business sector in fibre laser technology and manufacturing, improving production and manufacturing processes for a huge range of industries.

Fibre lasers allow for the precision engineering of complex shapes and have also been made with over 1,000 Watts of power (1kW) – more than enough to cut through an inch of steel.

Today, laser-based cutting and welding processes are giving us stronger, safer cars and lighter, faster planes. The technology of fibre lasers is also being applied to new challenges such as increasing internet capacity, creating renewable energy sources and improving health care diagnostics and treatment.

Makers of medical components have exploited the excellent beam quality and high power of fibre lasers to produce precision devices such as stents – the implants used in heart surgery. As a result of research by the university’s Optoelectronics Research Centre (ORC) there has been a 30% increase in the number of surgical stents manufactured with fibre lasers worldwide.

-

Hamir Patel

hamir.patel@russellgroup.ac.uk

020 3816 1316

-

Stephanie Smith

020 3816 1310

X

X